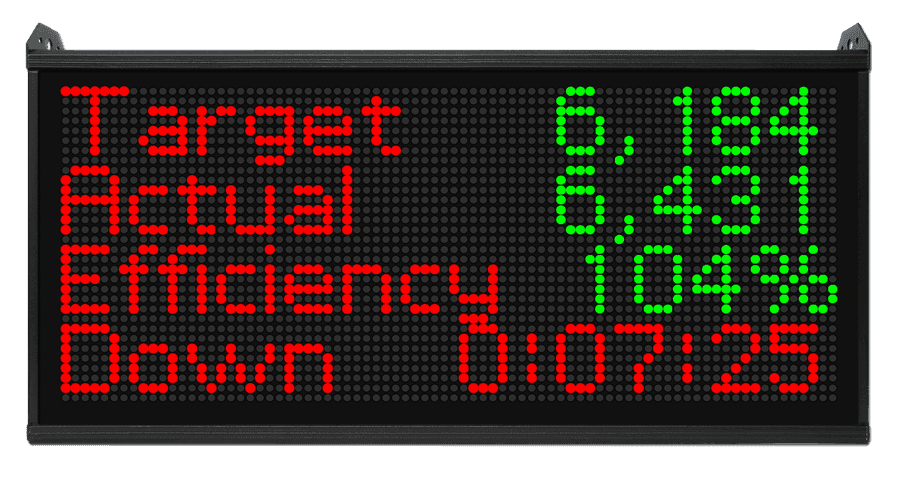

The Large Industrial Production Display Board from Robato Systems is designed for factory shop floors where production data must be visible from long distances. Featuring big LED digits (2–12 inches), multi-row layout and support for WiFi/Ethernet, PLC input, sensor integration and cloud/on-prem software, this display board is the go-to solution for real-time visibility in manufacturing plants.

This large-format LED Production Display Board acts as the central information hub on the factory floor. Operators, supervisors and managers can instantly see critical production metrics at a glance.

This helps improve production control, boost accountability and support lean manufacturing practices across your entire facility.

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Comprehensive high-visibility display capabilities for factory shop floors

Visible from 20 to 150 meters

RGB for color-coded status & alerts

Target, Actual, Efficiency, Rejection & more

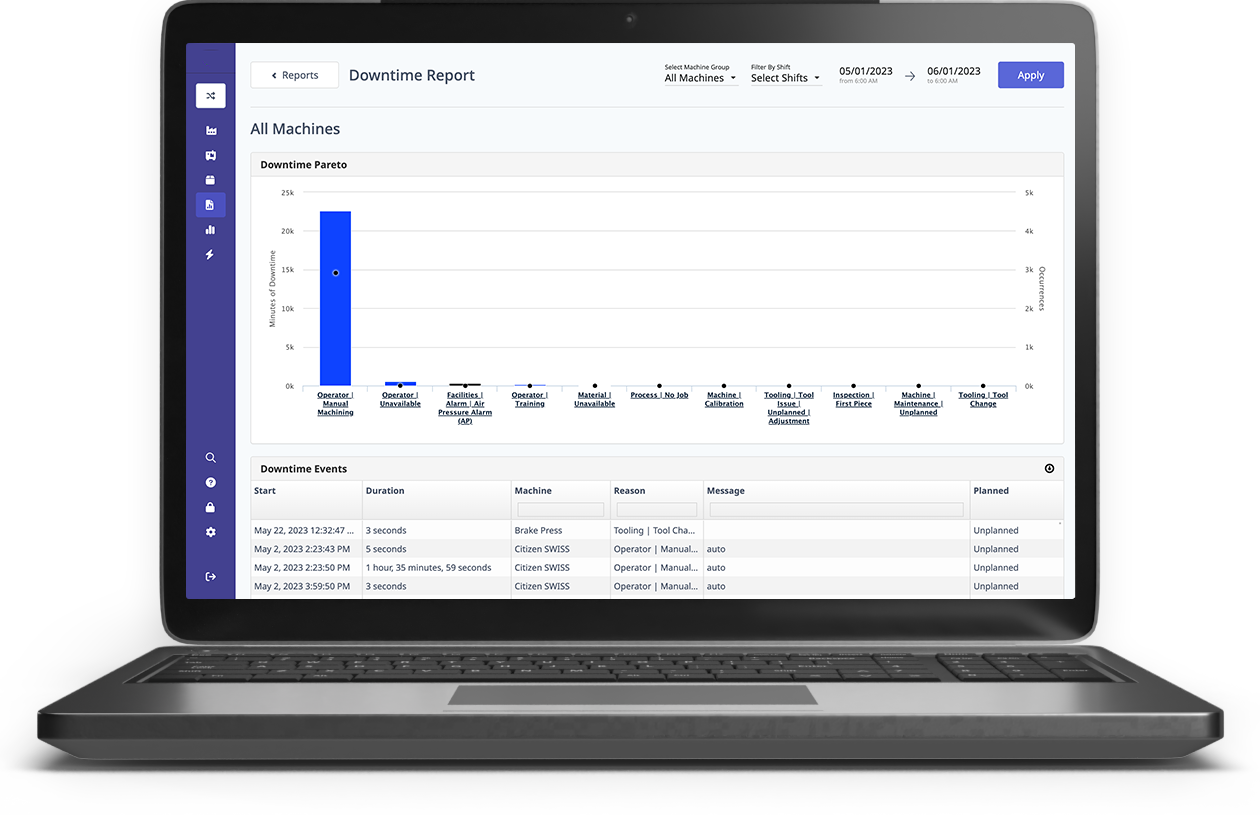

Network-enabled for real-time updates

Accepts pulses, PLC outputs & cloud data

Set parameters & row layout wirelessly

Sync with dashboards, mobile & TV displays

Rugged design for 24/7 operation

Rows, columns & data fields tailored to your needs

Multiple integration methods to suit your production environment

2–12 inches or custom

Ultra-bright Red or RGB

WiFi, Ethernet

Sensor, Push Button, PLC

Cloud SaaS, On-Prem, API/MQTT

Wall, hanging or gantry mount

110–240V AC / Optional 24V DC

Industrial-grade steel or aluminium

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Robato Systems can build your display in any size, layout or LED color. Explore more solutions or request a custom-made large display today.

Need specific sizes, layouts, or features? Contact us to discuss your custom large production display requirements.

Contact Us →Let Robato Systems transform your business with cutting-edge automation solutions. Book a free consultation and see the difference.