The Robato OEE Monitoring System is a real-time OEE monitoring software that helps factories measure and improve Overall Equipment Effectiveness (OEE) across machines, lines and plants. By combining data from LED production counters, PLCs, downtime logs and quality checks, the system gives you a live, accurate picture of Availability, Performance and Quality.

OEE is the most widely used KPI in manufacturing to understand how effectively machines are being used. Without a proper OEE Monitoring System, most factories:

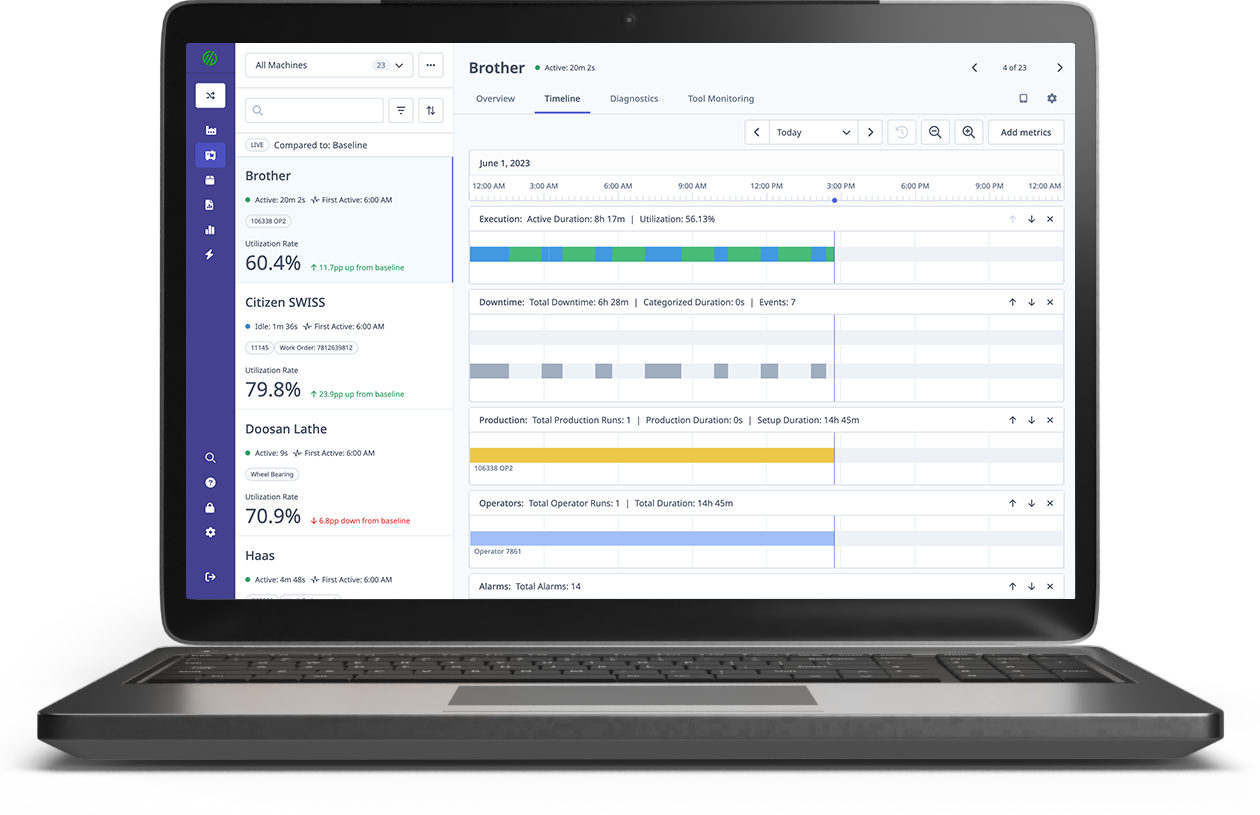

Robato's OEE Tracking System closes this gap by delivering live OEE dashboards that everyone can see — operators, supervisors and management.

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

The system collects data from multiple sources:

for counts and cycle times

for Target vs Actual and job details

for machine status and cycle information

manual or automatic downtime reasons

good vs rejected pieces

Once data is collected, the OEE monitoring software calculates:

based on planned vs actual running time and downtime

based on actual output vs theoretical maximum

based on good parts vs total produced

The system then combines these values to generate a real-time OEE percentage for each machine and line.

Live OEE data is pushed to web dashboards, Smart TV production dashboards and large production display boards. Supervisors can instantly spot:

Let Robato Systems transform your business with cutting-edge automation solutions. Book a free consultation and see the difference.

Everything you need to measure, monitor and improve OEE

Machine, line and plant-level views.

Clear contribution of each loss type.

Auto/manual reason capture.

Live achievement status.

Compare shifts and teams.

For low OEE, high downtime, quality drops.

OEE comparison across locations.

Seamless link with Robato hardware.

Choose what suits IT and compliance.

Choose the deployment model that fits your IT infrastructure and compliance requirements

Hosted as a SaaS platform, ideal for multi-plant enterprises that want unified dashboards and remote visibility.

Installed on a server within your factory, suitable for pharma and regulated industries with strict data policies.

Local data collection with selective cloud sync for management-level reporting.

LED counters, Smart counters, PLCs, sensors

Web browser, Android app, Smart TV

OEE, Availability, Performance, Quality

Cloud SaaS or On-Premise

REST APIs, MQTT, ERP/MES (optional)

Email, in-app notifications

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Connect your Production Counter LED Displays, Smart Counters, and Cloud / On-Prem Monitoring Systems to the Robato OEE Monitoring System and turn your plant into a truly data-driven factory.