BOOK A FREE TRIAL

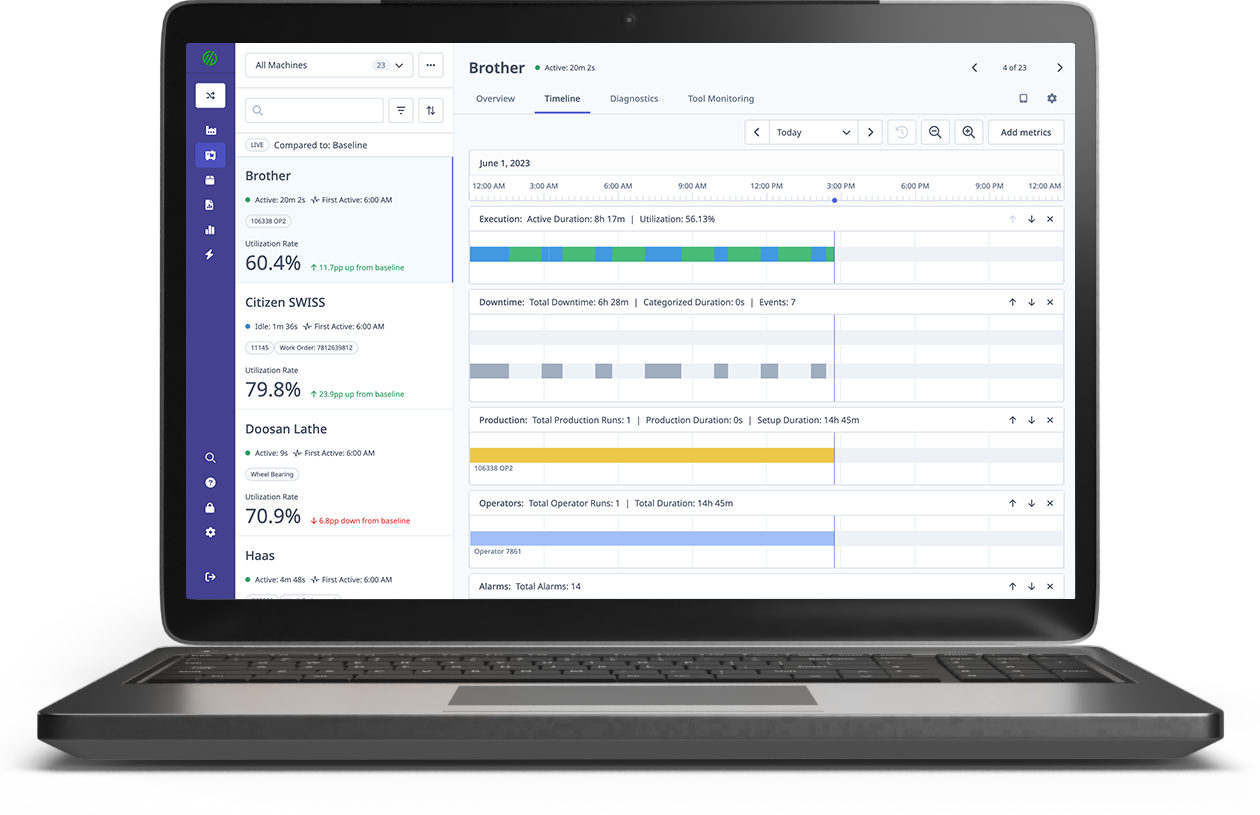

Industrial IoT Platform for Machines

Harness High-Frequency Machine Data at Scale

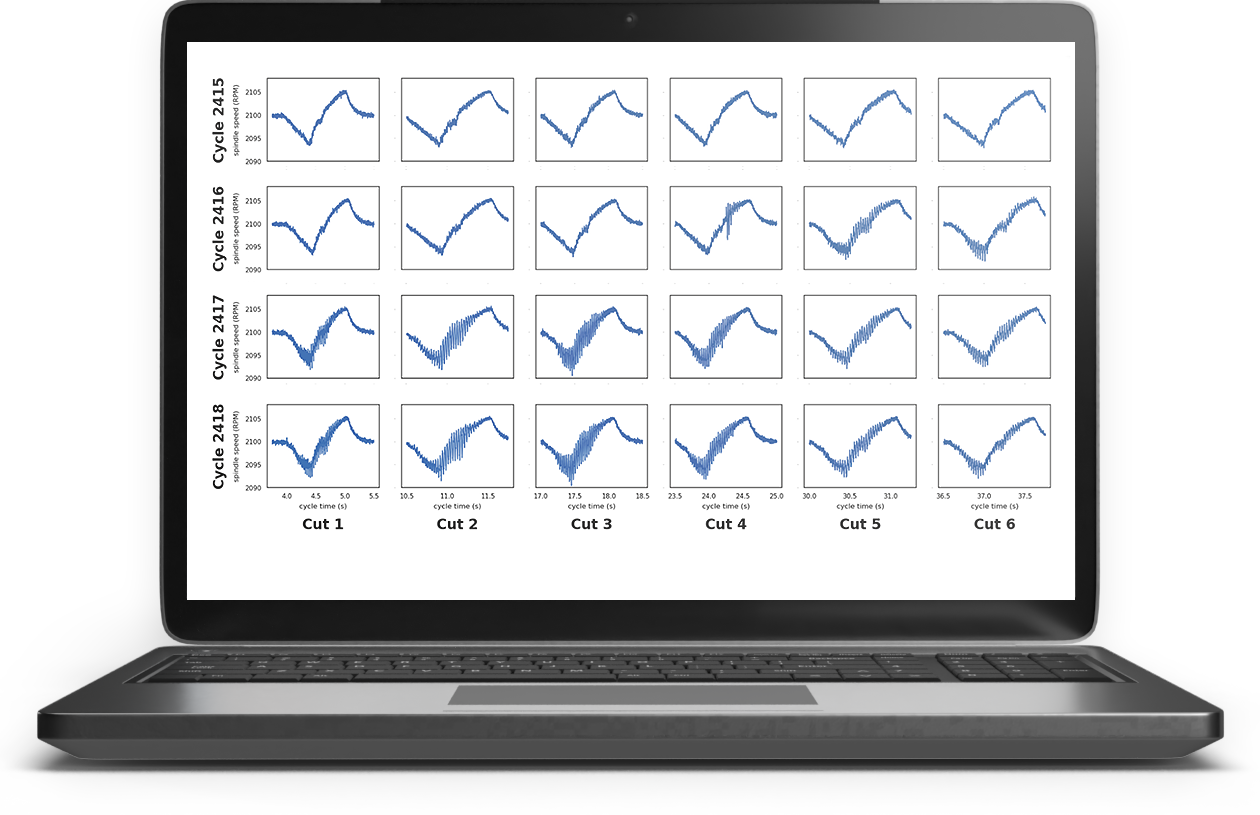

Bob Merril, Owner at BC Machining

Leveraging high-frequency data on spindle load to determine when the tools will fail, BC Machining can now detect a tool failure with 99% confidence up to 40 minutes before it fails.

Want to see MachinoX Pro in action first? BOOK A FREE TRIAL