The Robato Production Monitoring Solution brings together industrial-grade LED displays, sensors, PLC integration, Android apps and cloud/on-prem software to give you a complete, real-time view of your production. From live production counts to downtime, OEE, and machine status, everything is visible on dashboards, LED boards and Smart TVs.

A production monitoring solution is more than just a software screen or an isolated counter. It is a complete ecosystem of devices, applications and dashboards that continuously collect and present production data from your machines, lines and operators.

With Robato Systems, this ecosystem includes:

Let Robato Systems transform your business with cutting-edge automation solutions. Book a free consultation and see the difference.

Complete visibility across your entire production process

Real-time production count and output tracking

Shift-wise performance and target vs actual visibility

Machine status: Running, Idle, Breakdown, Maintenance

Automatic downtime detection and logging

Job ID, batch and order-wise tracking

OEE calculation (Availability, Performance, Quality)

Multi-line, multi-machine dashboards

Alerts and escalation via Andon systems

Multi-plant, multi-location cloud monitoring

Industrial-grade hardware for reliable data collection

Shows Target | Actual | Balance | Shift in large, bright characters. Available in single colour (Red) and RGB versions.

IR, proximity, photoelectric or encoder sensors, plus PLC I/O integration, collect cycle counts and machine status signals automatically.

Andon boards and machine status displays visually show Running/Idle/Breakdown and call alerts across the floor.

Displays live production and machine status for multiple machines or lines on large screens.

Powerful software for analytics and control

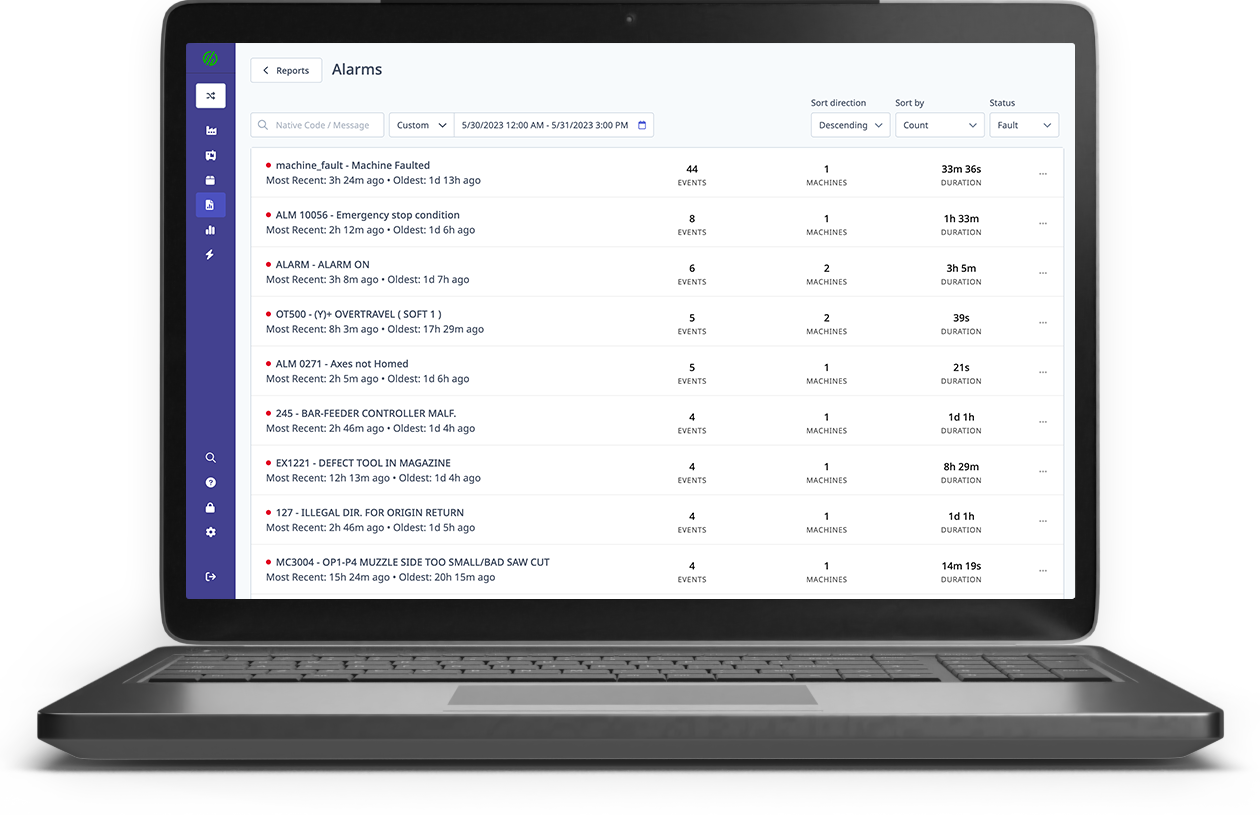

Central web-based platform that aggregates production data, provides dashboards and generates reports.

Advanced modules handle job tracking, batch management and detailed analytics.

Integrated modules for downtime monitoring and OEE tracking to measure losses and improve efficiency.

Allows supervisors and operators to update job ID, shift details, downtime reasons and see live production numbers directly on their phones or tablets.

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

PLC, sensors, counters, app, manual

WiFi, Ethernet, MQTT, TCP/IP, HTTPs

LED, Smart TV, web, mobile app

Cloud SaaS or On-Prem server

Andon, downtime, OEE, ERP/MES

Transform your factory with real-time visibility

Improves transparency and trust between shop floor and management

Reduces downtime with faster reaction to problems

Eliminates manual reporting and Excel-based tracking

Helps maintain realistic and measurable production targets

Supports Lean, TPM and continuous improvement initiatives

Enables performance comparisons by shift, line and operator

Makes production data accessible anytime, anywhere

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Explore related pages to learn more about our solutions

Let Robato Systems transform your business with cutting-edge automation solutions. Book a free consultation and see the difference.